Rack

Rack is a structure used for storing and displaying various items, especially in warehouse areas. They come in many forms and sizes to suit the type of products being stored and the available space. Shelving units help organize goods, making them easier to access and increasing efficiency in warehouse management.

Key features of rack

- Optimal space utilization

- Orderliness

- Easy access to goods

- Efficient product management

- Safety

- Increased usable space

- Weight capacity

Rack are often used in conjunction with material handling equipment, such as forklifts, to facilitate the storage and transportation of goods in warehouses. Transform your warehouse into a more organized system. Order today to receive special offers and installation services from our professional team.

Types of Racks

Shuttle system is a fully automated high-end storage solution consisting of rackings, pallet runners, and forklift trucks. This highly efficient storage method offers a new option to optimize space utilization and provides greater flexibility compared to traditional storage methods.

Advantages:

- Maximizes warehouse space usage

- Increases storage efficiency

- Supports both First In-First Out (FIFO) and First In-Last Out (FILO) storage

- Saves human resources and stacking equipment

- Enhance safety and reduce workplace accidents

Selective racks are an excellent choice for businesses requiring an easily accessible and highly flexible storage system.

Advantages:

- Easy accessibility: Direct access to each item

- Flexibility: Adjustable size and layout to meet various needs

- Low cost: Lower installation and maintenance costs compared to other storage systems

- Versatility: Suitable for a wide range of products, both light and heavy

- Efficiency: Improves inventory management, reducing search and retrieval times

- Space optimization: Increases vertical storage space, making efficient use of the warehouse

Electric Movable Pallet Racking system involves installing racks on mobile bases. Driven by electric motors, these racks can move along tracks. The system includes sensors to detect obstacles, enhancing safety during operations. Control panels are installed on the side posts for various controls.

Advantages:

- Saves up to 1/3 of warehouse space and minimizes the number of aisles

- Increases storage capacity by up to 90% of total warehouse space

- Adjustable beams to fit various pallet sizes

- Compatible with various storage and handling equipment

- Enhances storage efficiency

- Emergency function during power outages

VNA Pallet Racking is a type of selective rack that reduces aisle width to 1.6-1.8 meters, increasing storage space by up to 50% compared to standard selective racking systems. This system can support rack heights up to 14 meters.

Advantages:

- Optimizing space by reducing work pathways can result in overall space savings of up to 50%.

- Increase warehouse storage capacity with adjustable pallet racks, allowing for the addition of new pallet slots.

- VNA racks help utilize vertical space more effectively.

- Easy to assemble, disassemble, and reconfigure to accommodate changing storage needs.

- Adaptable to all types of goods by weight or volume, controlling load levels, or adding accessories.

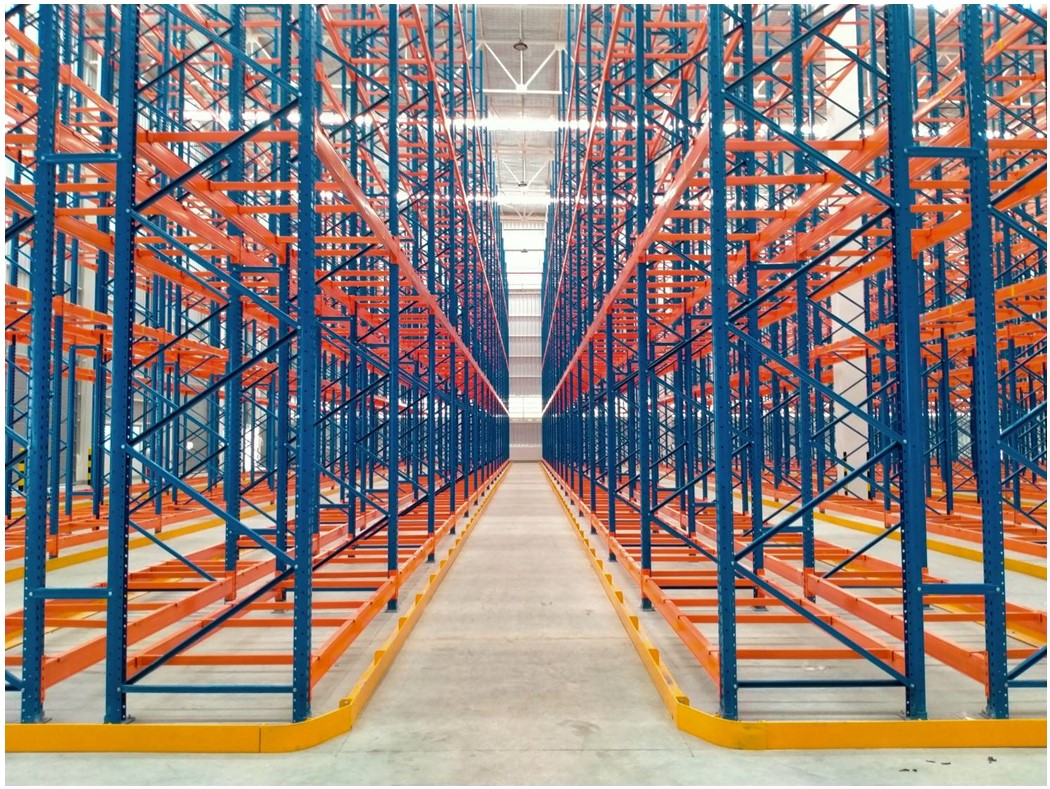

Drive-in racking systems are ideal for storing large quantities of the same product. Items are stored on the same level, using a First In Last Out (FILO) system.

Advantages:

- The design structure is aimed at saving up to 40-60% of space, allowing for more efficient utilization of warehouse space.

- Enhancing efficiency in stock transportation because products on each level vary, making storage and transportation easier.

- Adjusting shelf levels to suit various types of products for storage.

- Low investment compared to the volume of goods storage solutions.